Key Takeaways

- Precision and Automation: Tube laser cutting uses CNC-controlled systems to deliver consistent accuracy with tolerances as tight as the tube’s wall thickness, eliminating human error and ensuring identical parts across production runs.

- Material Versatility: The technology handles stainless steel, aluminum, and various alloys with outer diameters from 0.5 to 6.0 inches and wall thicknesses up to 0.5 inches, making it suitable for diverse applications.

- Cost and Efficiency Advantages: Semi-to-fully automated operation reduces labor costs, minimizes material waste through thin kerf cutting, and increases throughput while maintaining superior quality compared to traditional methods.

- Industry Applications: Automotive, aerospace, medical device, and construction industries rely on tube laser cutting for components requiring complex geometries, tight tolerances, and clean edges that facilitate easier assembly and welding.

- Material Selection Matters: Choose materials based on strength, weight, corrosion resistance, and bendability requirements—aluminum for lightweight applications, stainless steel for corrosion resistance, and specialty alloys for high-performance needs.

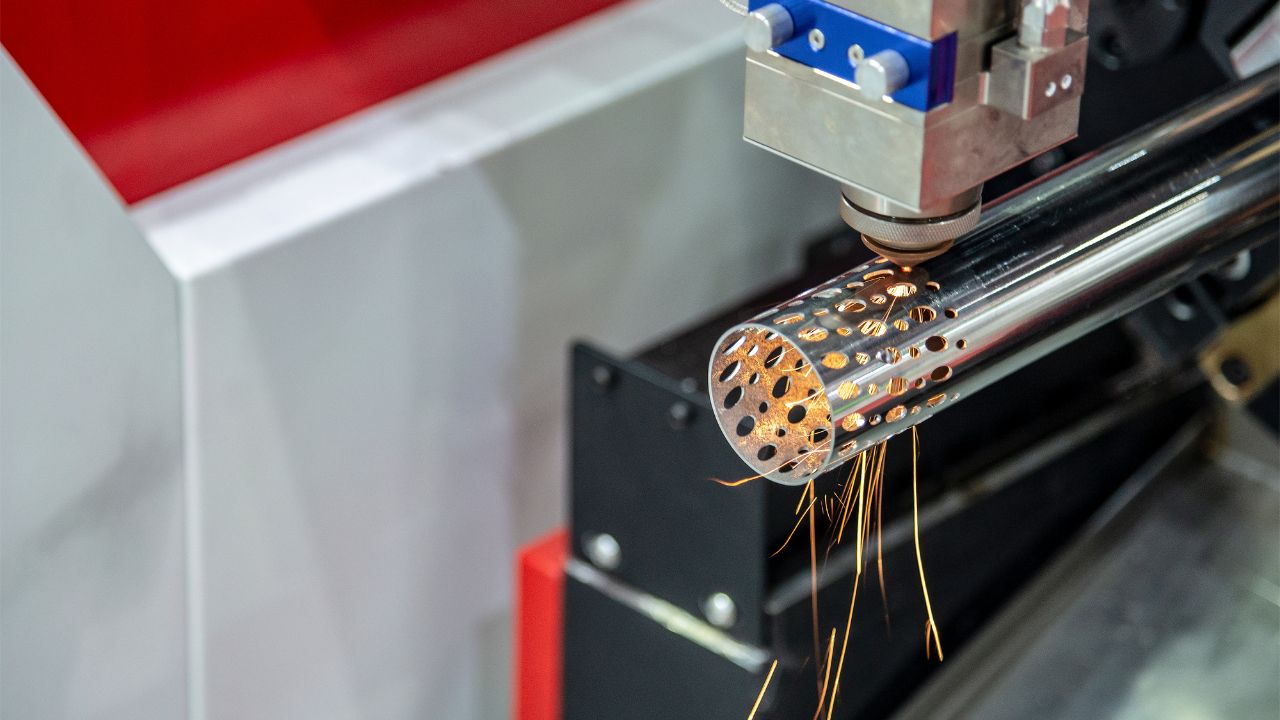

Tube laser cutting services have revolutionized precision manufacturing by delivering accuracy, speed, and complexity that traditional cutting methods cannot match. This technology uses focused laser beams to cut intricate patterns in tubular materials with minimal waste and maximum consistency. Industries ranging from automotive to aerospace rely on tube laser cutting services for components that demand tight tolerances and complex geometries.

CRD MFG, Inc., with its state-of-the-art tube laser cutting capabilities, plays a pivotal role in providing high-precision solutions for a variety of industries. Understanding how this process works, its advantages, and how to select the right service provider like CRD MFG, Inc. helps manufacturers optimize production quality while reducing costs.

This guide explores tube laser cutting fundamentals, applications, and practical considerations for integrating this technology into your manufacturing operations.

What Are Tube Laser Cutting Services and How Do They Improve Manufacturing Precision?

Tube laser cutting uses focused laser beams to cut, shape, and engrave tubular materials with exceptional accuracy. This non-contact process delivers precision that traditional cutting methods cannot match.

What is Tube Laser Cutting?

Tube laser cutting is an automated manufacturing process that uses high-powered lasers to cut precise shapes in metal tubes. The process begins with a 3D CAD model translated into machine instructions. The laser system feeds tube stock, rotates it to the correct position, and directs the laser beam to cut the material exactly as programmed.

This technology works through controlled material removal. The laser’s heat vaporizes metal at the cut point while the machine maintains precise positioning throughout the operation. The result is clean edges and complex geometries that traditional saws and mills struggle to achieve.

Why is Tube Laser Cutting Important for Precision Manufacturing?

Laser cutting eliminates human error through computer-controlled automation. The laser beam can create through-holes as small as the tube’s wall thickness and execute highly complex cuts that maintain tight tolerances across production runs. This consistency reduces manufacturing defects and eliminates variation between parts.

The technology also minimizes material waste. Laser cutting produces a thin kerf—the width of the cut—which removes less material than mechanical cutting methods. This precision means parts fit together correctly the first time, reducing scrap rates and lowering production costs while maintaining the exact specifications required for modern manufacturing applications.

The Tube Laser Cutting Process

Understanding how tube laser cutting operates helps manufacturers select the right equipment and materials for their projects. The process combines laser technology with CNC automation to deliver consistent results.

How Does Tube Laser Cutting Work?

Tube laser cutting uses CNC-controlled systems to execute precise cuts. The machine loads tube stock into the work area, positions it according to programmed coordinates, and applies the laser beam to the cut path. CNC integration ensures repeatable accuracy by controlling feed rates, rotation angles, and laser intensity throughout the operation.

Two primary laser types dominate the industry: fiber lasers and CO2 lasers. Fiber lasers offer versatility and compatibility with a wide range of materials, making them the standard choice for most metal fabrication. CO2 lasers excel with niche materials like titanium due to enhanced gas coverage during cutting. Laser power, measured in watts, determines both cut depth and speed—higher wattage enables deeper penetration and faster cycle times.

What Materials Can Be Processed Using Tube Laser Cutting?

Tube laser cutting handles most common metals including stainless steel, aluminum, and various steel alloys. The process accommodates tubes with outer diameters ranging from 0.5 to 6.0 inches and wall thicknesses up to 0.5 inches. This makes it suitable for applications from small-diameter medical tubing to larger structural components.

The technology works best with thin-walled materials where precision and clean cuts matter most. Material properties affect cutting parameters—softer metals like aluminum cut faster than hardened steel, while reflective materials may require specific laser wavelengths. Manufacturers must match laser type and power settings to material specifications for optimal results.

Advantages of Tube Laser Cutting Services

Tube laser cutting delivers measurable benefits across precision, efficiency, and cost performance. These advantages make it the preferred choice for modern manufacturing operations.

How Does Tube Laser Cutting Improve Manufacturing Precision?

Laser cutting executes complex geometries that traditional methods cannot achieve. The technology creates intricate patterns, tight-radius curves, and fine details while maintaining clean edges free from burrs or deformation. It also cuts channels and notches that facilitate easier bending and welding in downstream operations.

The process delivers highly complex, clean cuts with minimal material waste. Computer control eliminates human error and ensures each part matches design specifications exactly. This precision reduces fitting problems during assembly and eliminates the need for secondary finishing operations.

What Are the Key Benefits of Using Tube Laser Cutting Services?

Semi-to-fully automated operation drives high throughput and perfect repeatability. Once programmed, the system runs continuously with minimal supervision, producing identical parts at consistent quality levels. This automation allows manufacturers to scale production without compromising accuracy.

Material efficiency stands out as a key advantage. The thin kerf produced by laser cutting removes minimal material compared to saw blades or mechanical cutters. Less waste means lower material costs per part and reduced scrap disposal expenses. Combined with faster cycle times, these factors significantly improve production economics.

What Are the Financial Advantages of Tube Laser Cutting?

Automation reduces labor costs by minimizing manual handling and operator intervention. A single technician can oversee multiple machines, and the semi-to-fully automated process maintains high throughput without additional personnel. Setup times decrease because digital programming replaces physical tooling changes.

Production costs drop through improved efficiency and reduced waste. Traditional cutting methods require skilled operators, frequent tool changes, and extensive secondary operations. Tube laser cutting consolidates these steps into one automated process, lowering per-part costs while delivering superior quality that reduces rejection rates and rework expenses.

Applications and Industries Using Tube Laser Cutting

Tube laser cutting serves diverse industries that demand precision and complex geometries. From automotive components to medical devices, this technology enables manufacturing capabilities that traditional methods cannot match.

Which Industries Rely on Tube Laser Cutting?

Automotive manufacturing uses tube laser cutting for exhaust systems, chassis components, and roll cages where precise fitment is critical. Aerospace applications require the technology for hydraulic lines, fuel systems, and structural tubing that must meet exacting weight and strength specifications. Construction relies on laser-cut tubes for architectural frameworks, handrails, and structural supports.

Medical device manufacturing depends on tube laser cutting for surgical instruments, implantable components, and diagnostic equipment. The technology’s ability to maintain sterile, burr-free edges makes it essential for applications where cleanliness and precision directly impact patient safety. Each industry benefits from the consistency and accuracy that tube laser cutting delivers at production scale.

What Are the Common Products Made with Tube Laser Cutting?

Automotive exhausts utilize laser cutting for complex header designs, merge collectors, and flanges that optimize exhaust flow. The process creates intricate features and geometries difficult or impossible to achieve with traditional cutting methods. Medical components like endoscopic tubes and catheter guides require the microscopic precision that only laser cutting provides.

Structural products include HVAC ductwork, furniture frames, exercise equipment, and industrial machinery components. Laser cutting enables manufacturers to add mounting holes, slots, and custom profiles without secondary operations. This capability streamlines production while maintaining the dimensional accuracy needed for proper assembly and function across all applications.

CNC Integration in Tube Laser Cutting Services

CNC (Computer Numerical Control) technology transforms tube laser cutting from a manual process into a fully automated operation. This integration delivers precision and repeatability that manual methods cannot achieve.

How Does CNC Laser Cutting Enhance Tube Laser Cutting?

CNC systems control every aspect of the cutting process through programmed instructions. The system manages tube positioning, rotation angles, laser intensity, and feed rates with exact precision. Advanced sensors and feedback systems monitor the process in real-time, detecting any deviations from programmed parameters and making immediate adjustments to ensure accuracy.

This closed-loop control eliminates drift and variation during production runs. The CNC system compensates for material inconsistencies, thermal expansion, and mechanical wear automatically. Real-time monitoring catches errors before they become defects, maintaining quality without constant operator intervention.

What Are the Benefits of CNC Laser Cutting Services in Manufacturing?

CNC laser cutting ensures every part is identical to the last. The system delivers consistent accuracy across entire production runs, eliminating the variability inherent in manual operation. Automated quality control minimizes the need for post-cutting inspections and rework, leading to higher quality output and lower production costs.

The technology excels at producing intricate shapes with multiple cuts in a single piece without sacrificing structural integrity. CNC programming handles complex geometries that would require multiple setups with traditional methods. This capability reduces human error, improves scalability, and allows manufacturers to increase production volume while maintaining tight tolerances across all parts.

Choosing the Right Tube Laser Cutting Service Provider

Selecting the right tube laser cutting partner affects project timelines, quality, and costs. Several key factors determine which provider best fits your manufacturing needs.

How Do You Choose the Best Tube Laser Cutting Services Near Me?

Proximity matters for delivery speed and technical support. Local providers reduce shipping times and costs while enabling faster response to urgent orders or design changes. Geographic proximity also facilitates on-site consultations, prototype reviews, and immediate problem resolution when issues arise during production.

Evaluate local providers based on equipment capability, material expertise, and turnaround times. Check if they handle your tube sizes, materials, and complexity requirements. Established local shops often maintain relationships with regional material suppliers, which can expedite raw material procurement and reduce lead times for your projects.

What Are the Benefits of Choosing Tube Laser Cutting Services in OC?

Orange County tube laser cutting providers offer specialized expertise in industries dominant to the region. Local manufacturers understand California compliance requirements, including environmental regulations and material certifications specific to aerospace and medical applications. This regional knowledge prevents delays caused by regulatory oversights.

OC providers typically serve demanding industries like aerospace, defense, and medical devices, which drives higher quality standards and advanced capabilities. Working with local shops also supports face-to-face collaboration during design optimization and allows for easier quality inspections before full production runs.

How to Evaluate the Best CNC Laser Cutting Services for Your Project?

Assess equipment capabilities first. Verify the provider’s laser power range, maximum tube dimensions, and compatible materials match your specifications. Modern fiber laser systems indicate current technology and maintenance investment. Request details on machine age and maintenance schedules to gauge reliability.

Review past projects similar to yours. Ask for samples demonstrating the complexity, tolerances, and surface finish quality you require. Check certifications relevant to your industry—ISO 9001 for quality management, AS9100 for aerospace, or ISO 13485 for medical devices. Evaluate their CAD file handling capabilities and willingness to provide design-for-manufacturing feedback that can improve your parts before production begins.

Challenges and Considerations with Tube Laser Cutting

While tube laser cutting offers significant advantages, understanding its limitations helps manufacturers make informed decisions. Material constraints and process characteristics require careful evaluation during project planning.

What Are the Limitations of Tube Laser Cutting?

Tube laser cutting is generally reserved for thin-walled materials with wall thicknesses up to 0.5 inches. Beyond this limit, cutting speed decreases dramatically and heat-affected zones expand, compromising edge quality. Thicker materials often require plasma cutting or mechanical methods that handle greater material mass more efficiently.

Some cut materials exhibit a small halo of discoloration near cut edges due to backsplash—oxidation caused by reflected laser energy and process gases. While this rarely affects structural integrity, it may require secondary cleaning for visible applications or industries with strict cosmetic standards. Additionally, highly reflective materials like polished copper can deflect laser energy, requiring specific wavelengths or surface treatments before cutting.

What Should You Keep in Mind When Using Tube Laser Cutting Services?

Material choice directly impacts the manufacturing process, final product performance, and overall cost. Key selection factors include required strength, weight, corrosion resistance, and bendability for your specific application. Steel offers high strength and durability but adds weight and requires stainless or coated variants to prevent corrosion.

Aluminum provides lightweight, corrosion-resistant properties ideal for aerospace and automotive applications where weight reduction is critical. Its high ductility makes it easy to bend and form. Stainless steel delivers an excellent combination of strength and corrosion resistance, widely used in marine, medical, and food-grade applications. Copper excels in thermal conductivity for plumbing, HVAC, and refrigeration systems. Specialty alloys like titanium and chromoly offer exceptional strength-to-weight ratios but cost significantly more and present fabrication challenges. When searching for CNC tube bending services near me, manufacturers should balance material properties against project requirements and budget to optimize performance and manufacturing efficiency.

Why Tube Laser Cutting Services are Essential for Modern Manufacturing

Tube laser cutting has become indispensable in modern manufacturing environments. The technology delivers precision, efficiency, and capabilities that define competitive advantage in today’s industrial landscape.

How Tube Laser Cutting Services Enhance Manufacturing Efficiency and Quality?

The technology provides unparalleled precision, consistency, and efficiency in modern manufacturing operations. Automated CNC control eliminates human error while maintaining tight tolerances across production runs. Material waste decreases through thin kerf cutting, and labor costs drop through reduced manual intervention.

Advancements in laser technology have opened new frontiers in design and engineering that were previously impossible. Manufacturers can now produce complex geometries, intricate features, and tight-tolerance parts in a single automated operation. This capability serves critical industries—automotive, aerospace, medical, and construction—where precision directly impacts safety, performance, and regulatory compliance.

What Are the Next Steps in Integrating Tube Laser Cutting into Your Manufacturing Process?

Start by evaluating your current tube fabrication requirements. Identify parts that demand high precision, complex geometries, or consume excessive time with traditional methods. These represent the best candidates for transitioning to laser cutting.

Contact local tube laser cutting service providers to discuss your project specifications. Provide CAD files, material requirements, tolerances, and production volumes. Request samples and quotes from multiple providers to compare capabilities and costs. Many shops offer design-for-manufacturing consultations that can optimize your parts for laser cutting before production begins. This collaboration ensures your first project leverages the full advantages of tube laser cutting technology while establishing a manufacturing partnership that scales with your business needs.

Partner with CRD MFG, Inc. for Precision Tube Laser Cutting Services

CRD MFG, Inc. delivers precision tube laser cutting solutions that meet the demands of modern manufacturing. Our advanced CNC-controlled laser systems handle complex geometries, tight tolerances, and diverse materials from stainless steel to specialty alloys.

Whether you need prototype development or high-volume production runs, our experienced team provides the technical expertise and quality control your projects require. We serve automotive, aerospace, medical, and industrial applications with fast turnaround times and competitive pricing.

Contact CRD MFG, Inc. today to discuss your tube laser cutting needs. Our engineering team will review your specifications, recommend optimal manufacturing approaches—whether that involves laser cutting alone or combined with our tube bending services—and provide a detailed quote for your next project.