Key Takeaways

-

- Automated Precision: CNC tube bending uses computer-controlled machinery to eliminate manual operation variability, ensuring every bend replicates identically across production runs.

- Complex Geometry Capability: The technology produces intricate shapes with multiple bends, varying radii, and tight tolerances impossible to achieve through manual methods.

- Cost and Efficiency Gains: Automated quality control reduces material waste, minimizes rework, and enables faster production cycles with higher throughput than traditional bending.

- Industry-Critical Applications: Automotive, aerospace, and construction sectors depend on CNC tube bending for safety-critical components like exhaust systems, hydraulic lines, and structural supports.

- Design Optimization Matters: Material selection, bend radius constraints, and machine capabilities directly impact manufacturability and costs—working with experienced fabricators ensures optimal results.

CNC tube bending transforms metal fabrication through automated precision. This computer-controlled process, offered through CNC tube bending services, creates complex bends with consistent accuracy that manual methods cannot match. Modern manufacturing depends on CNC technology to produce everything from automotive exhaust systems to aerospace hydraulic lines with tight tolerances and minimal waste. CRD MFG, Inc. specializes in providing top-tier CNC tube bending services, ensuring precision and quality for every project.

This guide explains how CNC tube bending works, its advantages over manual methods, and key design considerations. You’ll learn about industry applications, integration with complementary processes like laser cutting, and how to optimize designs for cost-effective production. Whether planning mass production or custom fabrication, understanding CNC tube bending capabilities helps you make informed manufacturing decisions.

What Is CNC Tube Bending?

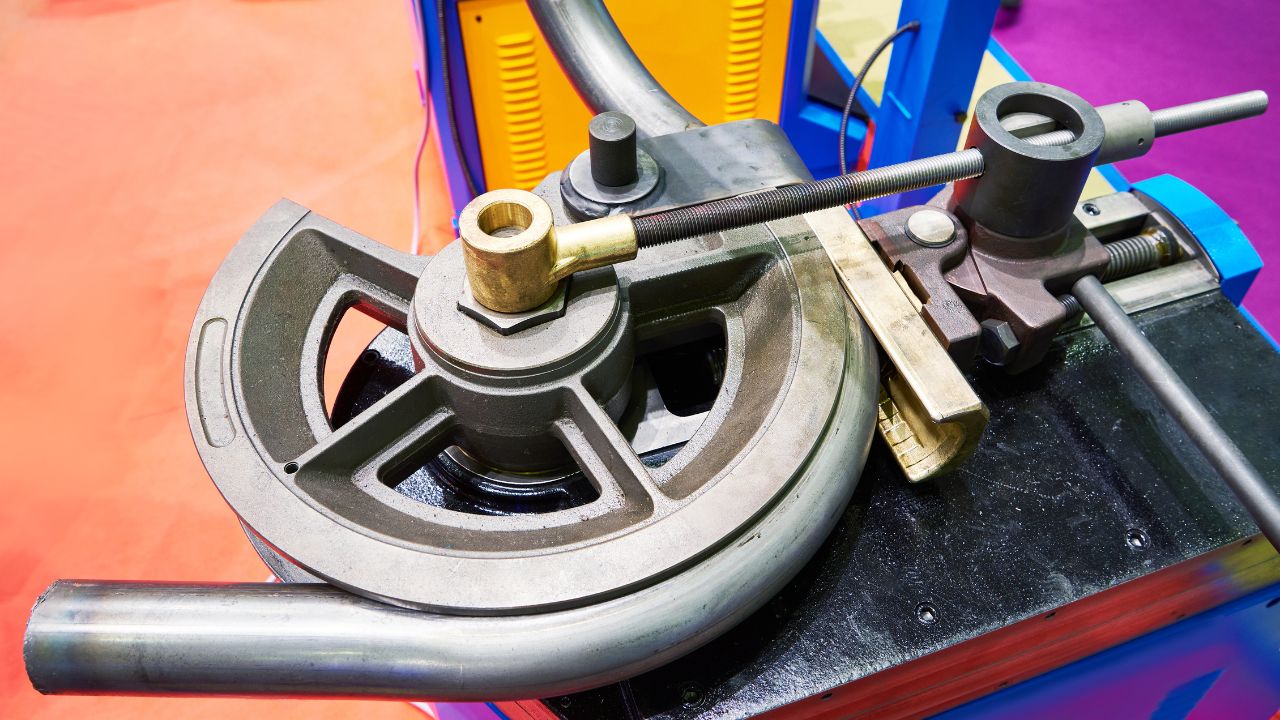

CNC tube bending automates precision metal forming through computer-controlled machinery. This section explains the technology, process mechanics, and core components that enable consistent, high-quality bends.

What Is CNC Tube Bending and How Does It Differ from Manual Bending?

CNC tube bending uses computer-controlled machinery to create complex, high-quality bends in metal tubes. The system follows programmed instructions to control tube positioning, rotation, and bending angles with zero variation between parts.

Manual and semi-automatic methods depend on operator skill, creating inconsistency. CNC eliminates human error by automating the entire process. Every bend replicates exactly, ensuring uniform quality across production runs.

How Does a CNC Tube Bender Work?

The process starts with a digital design programmed into the machine’s control system. The machine automatically feeds the tube, clamps it in position, and uses precision dies to form bends at specified angles and radii.

Advanced sensors monitor the process in real-time, detecting deviations from programmed parameters. The system makes immediate corrections to maintain accuracy. This automated quality control reduces post-bend inspections and rework, lowering production costs while improving part quality.

What Are the Components of a CNC Tubing Bender?

CNC tube benders rely on four core components: forming dies that shape the bends, clamping systems that secure the tube during bending, computer control systems that execute programmed instructions, and sensor networks that monitor accuracy in real-time. These integrated systems work together to deliver consistent, precise results.

How Does CNC Tube Bending Work and What Are Its Advantages Over Manual Bending?

CNC tube bending delivers superior precision and efficiency compared to manual methods. Automated control eliminates operator variability while increasing production speed and reducing waste.

How Does CNC Tube Bending Achieve High Precision and Consistency?

CNC systems deliver consistent accuracy across multiple bends by removing human error from the equation. The technology excels at producing intricate shapes with multiple bends in a single piece without compromising structural integrity.

Automated monitoring and real-time adjustments ensure every part meets exact specifications. Sensors continuously track bend angles, radii, and positioning, making instant corrections when deviations occur. This precision proves critical for industries requiring tight tolerances and repeatable results.

What Are the Key Advantages of CNC Tube Bending Over Manual Methods?

CNC tube bending offers five distinct advantages. First, precision and accuracy remain constant across production runs, eliminating manual operation variability. Second, complex geometries with intricate shapes and multiple bends become achievable without structural compromise.

Third, reduced material waste minimizes errors and scrap, generating significant cost savings with expensive materials. Fourth, streamlined continuous operation accelerates production cycles and increases throughput. Fifth, enhanced quality control through automated monitoring ensures parts meet exact specifications without extensive post-production inspection.

How Does CNC Tube Bending Improve Production Speed and Efficiency?

Streamlined, continuous operation enables faster production cycles and higher throughput than manual methods. The automated process eliminates setup time between parts and reduces operator intervention.

High-volume production benefits from fully automated systems with automatic feeding and robotic loading/unloading. These features provide substantial ROI by maximizing throughput while reducing labor costs. Continuous operation means machines run longer with minimal downtime, directly improving production efficiency.

How Is CNC Tube Bending Integrated with Other Manufacturing Processes?

CNC tube bending pairs seamlessly with complementary fabrication technologies. Laser cutting and advanced tooling expand design possibilities while streamlining production workflows.

How Does CNC Tube Bending Work with Laser Tube Cutting Services?

Laser tube cutting uses focused laser beams to cut, engrave, and shape tubes with exceptional precision. This non-contact process creates intricate features and complex geometries impossible with traditional cutting methods. As the tube rotates in a controllable lathe, lasers make precise cuts including through-holes as small as the tube’s wall thickness and channels that facilitate easier bending and welding.

Two laser types dominate: fiber lasers offer versatility across material types, while CO2 lasers excel with niche materials like titanium through enhanced gas coverage. The semi-to-fully automated process delivers high throughput with minimal material waste due to thin kerf width. Systems handle tubes from 0.5 to 6.0 inches in outer diameter with wall thicknesses up to 0.5 inches across stainless steel, aluminum, and steel alloys. Limitations include restriction to thin-walled materials and occasional discoloration halos near cut edges from backsplash.

How Are CNC Tube Benders Used for Complex Designs and Prototypes?

CNC tube benders fabricate parts with multiple bends, varying radii, and tight tolerances unachievable through manual methods. This capability revolutionized aerospace, automotive, and architecture industries where complex geometries serve both functional and aesthetic requirements.

Advanced machines feature multiple tool stacks, variable radius bending, and in-process left-hand and right-hand bending. These capabilities provide greater design freedom while eliminating secondary operations. Ongoing advancements in machine technology, tooling, and simulation software continuously expand what’s possible in complex tube design.

What Are the Benefits of CNC Tube Bending?

CNC tube bending offers distinct advantages for both mass production and custom fabrication. Automated precision ensures consistency at scale while maintaining flexibility for specialized applications.

How Does CNC Tube Bending Ensure Consistency in Mass Production?

CNC systems ensure every bend replicates identically, delivering unparalleled precision and efficiency across production runs. Automated monitoring and real-time adjustments guarantee final products meet exact specifications without variation.

This consistency minimizes post-bend inspections and rework, reducing production costs while improving quality. Manufacturers achieve higher throughput with confidence that each part matches design specifications, eliminating the quality fluctuations inherent in manual processes.

Why Is CNC Tube Bending Ideal for Custom Bending Needs?

Custom tube fabrication transforms raw tubing into finished components through a multi-step process requiring careful planning, advanced equipment, and expert craftsmanship. The process flows through material selection, cutting, shaping, welding, and finishing stages to meet precise specifications.

CNC technology delivers design versatility, performance optimization, and seamless integration with other components while ensuring reliability and safety. This flexibility enables application-specific solutions across diverse industries, from one-off prototypes to specialized production runs. The same precision that benefits mass production applies to custom work, guaranteeing repeatability when designs require future replication.

What Industries Rely on CNC Tube Bending?

CNC tube bending serves critical functions across multiple industries. Automotive, aerospace, and construction sectors depend on precision bent tubes for both structural and performance applications.

How Is CNC Tube Bending Used in the Automotive Industry?

Automotive manufacturers rely on CNC tube bending for exhaust systems, roll cages, and fuel lines. These components demand precise bends to fit vehicle specifications while maintaining structural integrity and performance standards. CNC precision ensures consistent fitment across production runs, critical for both safety-critical structural components and performance systems requiring optimal flow characteristics.

What Role Does CNC Tube Bending Play in Aerospace Manufacturing?

Aerospace applications require CNC tube bending for hydraulic lines, fuel systems, and structural supports. Complex geometries serve both functional requirements and aesthetic specifications in aircraft design.

Specialty alloys like titanium provide exceptional strength-to-weight ratios essential for high-performance aerospace applications. CNC precision proves critical when working with these expensive materials, where tolerances are tight and material waste must be minimized. Companies offering aerospace tube fabrication services use this technology to enable intricate routing of systems within confined aircraft spaces while maintaining structural reliability.

How Does CNC Tube Bending Benefit the Construction Industry?

Construction projects rely on CNC tube bending for scaffolding, handrails, and architectural elements. The technology enables both functional structural components and decorative features that meet design specifications.

Precision bending ensures safety-critical scaffolding components meet load requirements while architectural elements achieve desired aesthetic profiles. CNC consistency allows prefabrication of components that fit perfectly on-site, reducing installation time and costs.

How to Optimize Designs for CNC Tube Bending?

Design optimization balances material properties, bend geometry, and manufacturing capabilities. Proper planning reduces costs while ensuring parts meet specifications.

What Are the Design Considerations for CNC Tube Benders?

Minimum bend radius depends on material properties and wall thickness. Tighter bends increase wrinkling or collapse risk, while material ductility determines cracking susceptibility. Less ductile materials crack more easily during bending. Complex designs require specialized tooling and longer setup times, raising production costs. Working with experienced fabrication professionals optimizes parts for manufacturability, ensuring ambitious designs achieve precision and quality.

Material selection impacts bendability and performance. Steel offers high strength and durability for heavy-duty applications but adds weight and corrosion risk unless stainless or coated. Aluminum provides lightweight, corrosion-resistant properties ideal for aerospace and automotive weight reduction, plus high ductility for easier bending. Stainless steel combines strength with corrosion resistance for marine, medical, and food-grade applications. Copper’s thermal conductivity suits plumbing, HVAC, and refrigeration systems. Specialty alloys like titanium and chromoly deliver exceptional strength-to-weight ratios but cost more and bend harder, limiting use to high-performance applications.

Pipes and tubes serve different purposes. Pipes transport fluids and gases, sized by nominal inside diameter with thicker walls for pressure resistance and less exacting specifications. Tubes handle structural and precision applications, sized by exact outside diameter and wall thickness with tighter tolerances, lighter weight, and easier workability. Choose pipe bending for fluid transport in plumbing, industrial systems, and pressure vessels. Choose tube bending for precision applications requiring tight tolerances, complex geometries, and smooth interiors.

How Can You Ensure the Most Cost-Effective CNC Tube Bending Service?

Machine capacity represents the most critical selection factor. Capacity includes maximum and minimum tube diameter and wall thickness ranges. Oversized machines waste money through excessive tooling costs and energy consumption. Undersized machines cannot perform required work.

Evaluate machine capabilities against part complexity. Machines with multiple tool stacks, variable radius bending, and in-process left-hand and right-hand bending provide greater design freedom. User-friendly interfaces, programmable controls, and simple setup procedures reduce operator training time and improve productivity. For high-volume production, fully automated systems with automatic feeding and robotic loading/unloading deliver significant ROI through increased throughput and reduced labor costs.

What Are the Challenges in CNC Tube Bending?

CNC tube bending faces material and process limitations that affect production. Understanding these challenges and mitigation strategies ensures successful outcomes.

What Common Problems Can Occur in CNC Tube Bending?

Tighter bend radii increase wrinkling or collapse risk as material properties reach their limits. Less ductile materials crack more easily during bending, restricting design options. Complex designs require specialized tooling and longer setup times, driving up production costs.

Material-specific limitations constrain certain processes. Tube laser cutting generally works only with thin-walled materials. Laser-cut materials may show small discoloration halos near cut edges from backsplash, requiring additional finishing for cosmetic applications.

How Can These Challenges Be Mitigated in CNC Tube Bending Services?

Advanced sensors and feedback systems monitor processes in real-time, detecting deviations from programmed parameters. Immediate adjustments ensure accuracy and minimize defects before they become costly problems.

Machine technology, tooling, and simulation software advancements continue expanding complex tube design possibilities. Working closely with experienced fabrication professionals helps designers optimize parts for manufacturability from the start. Proper material selection based on application requirements prevents many common bending issues, eliminating problems before production begins.

Why Choose CNC Tube Bending for Your Next Manufacturing Project?

CNC tube bending delivers consistent accuracy that eliminates manual operation variability. The technology excels at producing complex geometries with multiple bends while maintaining structural integrity. Automated quality control minimizes material waste and reduces production costs, while streamlined operation enables faster production cycles and higher throughput.

The process proves versatile enough for custom fabrication yet maintains consistency for mass production. Industries from automotive to aerospace to construction depend on CNC precision for critical applications. Integration with laser tube cutting services expands design possibilities beyond traditional fabrication limits. Advanced monitoring systems ensure every part meets exact specifications without extensive inspection.

CNC tube bending combines precision, efficiency, and scalability into a single manufacturing solution. Whether producing complex prototypes or high-volume production runs, the technology delivers reliable results that meet demanding specifications while controlling costs.

Partner with CRD MFG, Inc. for Precision CNC Tube Bending

CRD MFG, Inc. delivers expert CNC tube bending services for industries demanding precision and reliability. Our advanced machinery handles complex geometries, tight tolerances, and diverse materials from aluminum to specialty alloys. Whether you need custom prototypes or high-volume production, our experienced team optimizes designs for manufacturability while controlling costs.

We integrate CNC tube bending with complementary services like laser cutting to expand your design possibilities. Our quality control systems ensure every part meets exact specifications without extensive inspection delays. Contact CRD MFG, Inc. today to discuss your tube bending requirements and discover how our tube bending solutions can enhance your next manufacturing project.